Hacking Meat is an online conversation exploring how can information and technology be used to hack (or reimagine) a more sustainable, profitable and healthy future of meat. Join the conversation and share your ideas or product requests in the comments, on Twitter using #hackmeat, on Facebook or at the Hack//Meat hackathon happening December 7-9 in NYC.

Guest post by John Bailey of Top 10 Produce LLC and Dick Stoner of Locale Chesapeake

While farmers rely on social networks to market their products, the length of the supply chain can often dilute the quality of communication to consumers. When interacting with mainstream food manufacturers, producers must collect source data in a standard reusable format that is interoperable with the information systems used across the supply chain.

While farmers rely on social networks to market their products, the length of the supply chain can often dilute the quality of communication to consumers. When interacting with mainstream food manufacturers, producers must collect source data in a standard reusable format that is interoperable with the information systems used across the supply chain.

We believe that this kind of interoperability is key to helping people build healthier communities through better food. To this end, Top 10 Produce LLC is launching a new information system next year to help our nationwide network of farms sell their agricultural products using any online sales platform. Here’s how it works:

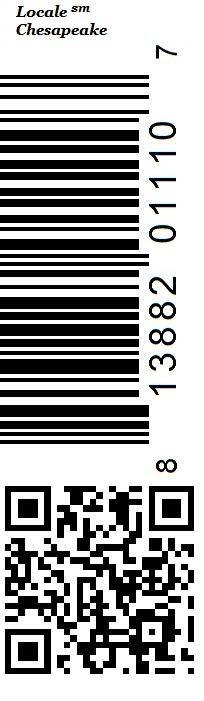

Our software system transforms branded UPC codes into branded Locale Quick Response codes. These codes are then redirected to any HTML5 profile that is controlled by the farmer. Though the UPC alone acts as a QR code, we add QR codes to packaging because consumers understand how they work. Nevertheless, we believe that the UPC code will become a stand-alone format in the future, such that consumers will scan our branded products to learn more about their farmers and the Locale of products sold under our brand name.

In short, Top 10 Produce LLC allows our data to be syndicated through our central database and follows the information along the whole supply chain – from farm to fork. This streamlined routing averts inaccuracies from occurring throughout the syndication along the supply chain. It also prevents information from becoming stale because the landing page can be updated at any time.

In short, Top 10 Produce LLC allows our data to be syndicated through our central database and follows the information along the whole supply chain – from farm to fork. This streamlined routing averts inaccuracies from occurring throughout the syndication along the supply chain. It also prevents information from becoming stale because the landing page can be updated at any time.

For example, the QR code of this ground beef label can redirect to any number of HTML5 versions viewed on a mobile device. This flexible view enables producers to sell

items using any online sales platform and without the need to adjust packaging. One farmer may also link to multiple sales platforms, which provides a marketing advantage. Scan the QR code on the image to the right to see an example of how this works.

Do you use technology to market your products and share traceability information with your customers? What works and what doesn’t? Let us know in the comments, on Twitter using #hackmeat, on Facebook or at the Hack//Meat hackathon happening December 7-9 in NYC.

___________________________________

John Bailey is a co-founder and Executive Director of Top 10 Produce LLC, a technology-centered brand holding company serving independent farms throughout the United States and Canada. Besides heading Top 10 Produce, Bailey is also a dispute resolution attorney with a practice focused on agricultural law, and a member of the technology working group for the Produce Traceability Initiative (PTI), an industry-led, supply chain-wide initiative designed to improve traceability procedures.

John Bailey is a co-founder and Executive Director of Top 10 Produce LLC, a technology-centered brand holding company serving independent farms throughout the United States and Canada. Besides heading Top 10 Produce, Bailey is also a dispute resolution attorney with a practice focused on agricultural law, and a member of the technology working group for the Produce Traceability Initiative (PTI), an industry-led, supply chain-wide initiative designed to improve traceability procedures.

Dick Stoner specializes in Online Marketplace systems. Since 2002, he has worked with commercial real estate information systems to provide brokers, agents and owners of real estate a set of affordable tools for growing their businesses. Beginning in 2009, he became part of a nationwide team that is implementing online inventory and search systems for the food industry, which involves hundreds of providers and millions of buyers, many of whom are concerned with the source of the food products they purchase and consume. ” Source Verified” food systems are being developed using RFID technology and GS1 bar-codes.

Dick Stoner specializes in Online Marketplace systems. Since 2002, he has worked with commercial real estate information systems to provide brokers, agents and owners of real estate a set of affordable tools for growing their businesses. Beginning in 2009, he became part of a nationwide team that is implementing online inventory and search systems for the food industry, which involves hundreds of providers and millions of buyers, many of whom are concerned with the source of the food products they purchase and consume. ” Source Verified” food systems are being developed using RFID technology and GS1 bar-codes.

In 2012, online systems for Environmental Credits — land preservation, wetlands, stream valley, and upcoming nutrient offset credits will be offered through a new program that will serve states with Environmental Trading Credit programs, particularly in the Chesapeake Bay watershed.

Pingback: Technology to help the local meat farmers | Local food systems in the Middle Atlantic Region